Injection Molding

Cavallero Plastics has a full range of molding machines to meet your needs. From 5 to 800 tons, both hydraulic and all electrics, we are constantly updating our molding machines and auxiliary equipment in order to produce the highest quality parts. Our experienced staff is always looking for ways to increase productivity, which translates to better quality and economy for our customers.

Stack molds can increase production in the same size injection molding press.

Stack molds can increase production in the same size injection molding press.

Molding Medical and Food Packaging maintaining a Clean Enviroment is critical.

Molding Medical and Food Packaging maintaining a Clean Enviroment is critical.

Robots can reduce costs and improve quality by precisely doing routine tasks.

Robots can reduce costs and improve quality by precisely doing routine tasks.

Injection molding press for small injection molds.

Injection molding press for small injection molds.

Robot removing parts from a large mold and placing the parts on a conveyor.

Robot removing parts from a large mold and placing the parts on a conveyor.

A large robot can handle large parts or many small parts as shown in this photo.

A large robot can handle large parts or many small parts as shown in this photo.

Open Mold showing highly polished core.

Open Mold showing highly polished core.

Large parts require large highly polished molds to manufacure smooth precise parts.

Large parts require large highly polished molds to manufacure smooth precise parts.

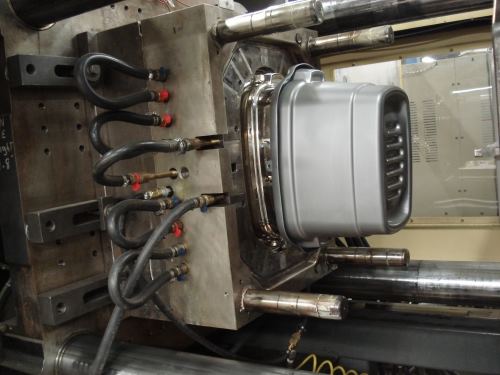

Injection Molding Press with Mold mounted.

Injection Molding Press with Mold mounted.

Large Parts Require Large Presses and Cavallero Has them!

Large Parts Require Large Presses and Cavallero Has them!

Fully Automated System to sort and assembly parts into a sealed assembly.

Fully Automated System to sort and assembly parts into a sealed assembly.

Molding clean percise parts requires a clean space and well trained employees.

Molding clean percise parts requires a clean space and well trained employees.

Capabilities:

| Injection Molding Machines: 45 Injection Molding Machines from 5 - 800 tons. Tonnage is used to rate the size of injection molding machines. It is the measure of the clamp pressure the machine can create. Larger parts and multi cavity molds require larger presses. |

| Two-shot molding – Allows two colors or different materials to be combined. |

| Stack molding – A mold design that allows for more cavities to run in a smaller press. |

| Clean Room molding – Molding in a controlled environment usually used for medical and food products. |

| Insert Molding – Installing metal threads or another feature while injection molding. |

| Vertical/Horizontal molding – The orientation of the injection molding press. Horizontal is the most common configuration. |

| Rapid Prototyping – 3D printing, machining plastic parts, aluminum molds, and other methods are used to make prototype parts for testing and validation. |

| Micro-molding – Extremely precise injection molding of small parts. |

| Automated and Hand-loaded Insert molding – Injection molding inserts in high or low volume applications. |

| In-mold decorating – Designing and installing engraving or placing a label inside a mold so the part when molded is already decorated. |

| UL stands for Underwriters Laboratories and means a products meets their safety standards. |

| FM stands for Factory Mutual Approved Products – FM approval deploys scientific research and testing to ensure products comply with the highest safety standards to prevent property losses. |

Full Spectrum of Commodities and Resins:

| Commodity – lower cost materials |

| PP – Polypropylene – resilient material with good chemical resistance and moderate stiffness. |

| PS – Polystyrene – Very stiff and can be used to manufacture thin wall products, poor chemical resistance and lower impact strength than other materials. |

| PE – Polyethylene – most popular resin used in the world, good impact resistance, flexible, soft, good UV & chemical resistance used in milk jugs, outdoor toys, bottle caps and many other products. |

| SAN - Styrene acrylonitrile resin is a copolymer plastic consisting of styrene and acrylonitrile. It is widely used in place of polystyrene owing to its greater thermal resistance. |

| PVC - Polyvinyl chloride resin is a thermoplastic resin which can clear or colored and be made very stiff or flexible. Widely used for pipe in construction as it is easily glued and also used in Consumer Food wraps and packaging. |

| ABS - Acrylonitrile Butadiene Styrene. ABS is an impact-resistant engineering thermoplastic & amorphous polymer. High impact strength and better chemical resistance than PS. Used in Automotive and packaging applications. |

| Acrylic is a transparent plastic material with outstanding strength, stiffness, and optical clarity. Bonds well with adhesives and solvents, and has superior weathering properties … |

| Acetal also called polyacetal and polyoxymethylene (POM), is a general purpose, semi-crystalline, engineered thermoplastic. Acetal is commonly used for parts that need to be very stiff, have low surface friction and good dimensional stability. |

| Engineered Resins – more advanced materials which have special properties and are more expensive to use. |

| PC - Polycarbonate a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. |

| TPE Thermoplastic elastomers plastics which are an engineering marvel, combining the looks and flexibility of thermosetting rubber with the processing prowess of plastics. |

| PET - Polyethylene terephthalate has characteristics such as high transparency, high mechanical and excellent gas barrier properties. Used for various of applications, such as packaging, industrial parts and sheets etc. |

| PBT - Polybutylene Terephthalate is a semi-crystalline engineering thermoplastic material. It has similar properties and composition to polyethylene terephthalate (PET). It is a member of polyester family. |

| NORYL is resin family which is a combinations of SABIC’s proprietary polyphenylene ether (PPE) technology blended with high impact polystyrene (HIPS), polypropylene (PP), polyamide (PA), or thermoplastic elastomers (TPE). |

| High Temperature resins |

| PPS - Polyphenylene sulfide plastic is a semi crystalline, high temperature thermoplastic polymer. It is a very chemically resistant polymer with very good mechanical strength, even at temperatures above 392°F. It has low water absorption, good dimensional stability and excellent electrical properties |

| PEEK – Polyetheretherketone - is a semi-crystalline, high-performance engineering thermoplastic. This rigid opaque (grey) material offers resistance to chemicals, wear, fatigue and creep as well as exceptionally high temperature resistance, up to 260°C (480°F). |

| PEI - Polyetherimide is a blend of polyphenylene ether (PPE) and polystyrene. With additive packages for impact strength (non-brominated FR, reinforcements, etc.) a family of products can be made featuring UL-VO to UL HB and UL 5V, high stiffness, and high impact strength. |

| Polysulphone - remains stable resisting creep and deformation under continuous load and elevated temperatures. They have high tensile strength and as temperatures increase, flexural modulus remain high. Withstands exposure to soap, detergent solutions and some hydrocarbon oils, even at elevated temperatures under moderate stress levels. |

| Ultem - a family of polyetherimide (PEI) thermoplastic materials manufactured by SABIC. Like all PEI materials, Ultem™ is similar to PEEK, but with lower impact strength and a lower useable temperature. |

| Radel - polyphenylsulfone (PPSU) produced by Solvay delivers the highest performance of our sulfone polymers. Offered in transparent and opaque color offers impact strength similar to polycarbonate (PC) and better chemical resistance than polyetherimide (PEI). |