Mold Making

Our complete and advanced mold making facility provides a fundamental advantage as a complete product solution partner. Whether redesigning an existing mold or embarking on a brand new project, our team is able to deliver the highest quality tooling for injection molding with some of the shortest lead times in the industry.

We excel in this process through a cohesive paperless system lined to our engineering and production teams. A proactive approach manages and accelerates responses to inquiries and avoids delays in mold completion when dealing with difficult 3D geometric designs. Our tool room is equipped with the latest resources in mold making technology, including CAM, CNC milling, grinding, EDM, inspection and more. These characteristics, coupled with a highly skilled staff encompass our mold-making department.

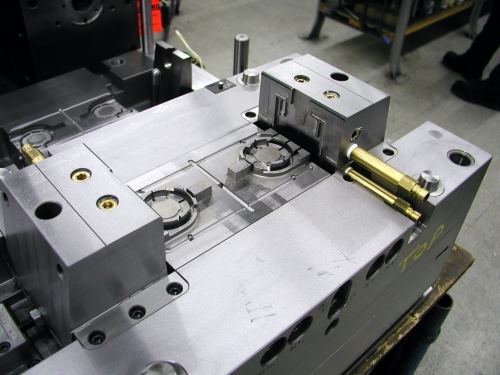

Cavallero has a complte mold building and repair department with the latest equipment.

Cavallero has a complte mold building and repair department with the latest equipment.

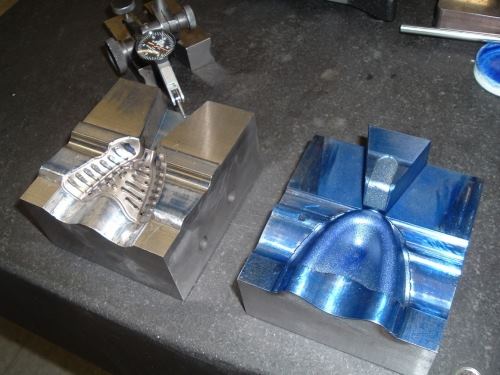

EDM - Electrical Discharge Machine can be used to create metal mold components that can not be made by tradational machine tools.

EDM - Electrical Discharge Machine can be used to create metal mold components that can not be made by tradational machine tools.

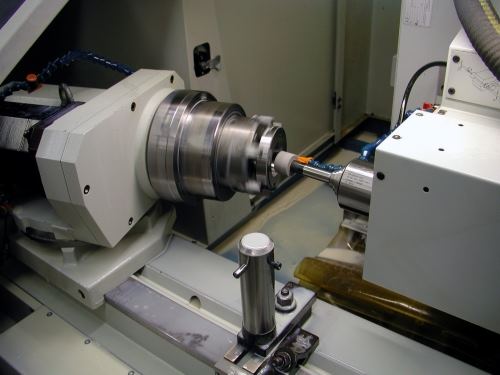

Precise machine tools are used to make precise molds.

Precise machine tools are used to make precise molds.

Complex mold components require precise manufacturing processes.

Complex mold components require precise manufacturing processes.

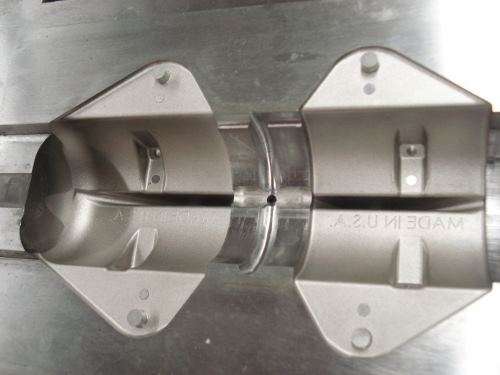

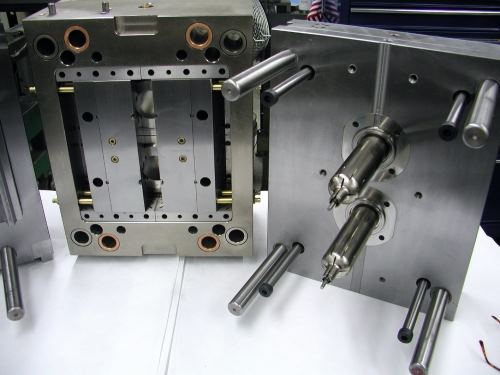

An injection mold has two halves and each must be precisely made and fit togther prefectly.

An injection mold has two halves and each must be precisely made and fit togther prefectly.

Two cavity mold shown opened.

Two cavity mold shown opened.

EDM machine uses in house made custom carbon tooling.

EDM machine uses in house made custom carbon tooling.

Precise surface grinding is critical for building quality injection molds.

Precise surface grinding is critical for building quality injection molds.

Computer controlled machining center with multi tool functions.

Computer controlled machining center with multi tool functions.

Capable of precise grinding, lapping, deburring and polishing.

Capable of precise grinding, lapping, deburring and polishing.

Precise measuring with a variety of tools.

Precise measuring with a variety of tools.

Using an EDM machine requires many carbon tools for each part of the process.

Using an EDM machine requires many carbon tools for each part of the process.

Precise EDM work requires precise carbon tooling.

Precise EDM work requires precise carbon tooling.

Machinist making a tool change in machining center.

Machinist making a tool change in machining center.

Often referred to as a "Bridgeport" this is a multipurpose milling machine.

Often referred to as a "Bridgeport" this is a multipurpose milling machine.

Six cavity mold half shown to manufacture complex parts.

Six cavity mold half shown to manufacture complex parts.

Large two cavity mold to manufacture two long parts at the same time.

Large two cavity mold to manufacture two long parts at the same time.

Large molds take precision work on a large scale.

Large molds take precision work on a large scale.